Vibration Diagnostics and Troubleshooting

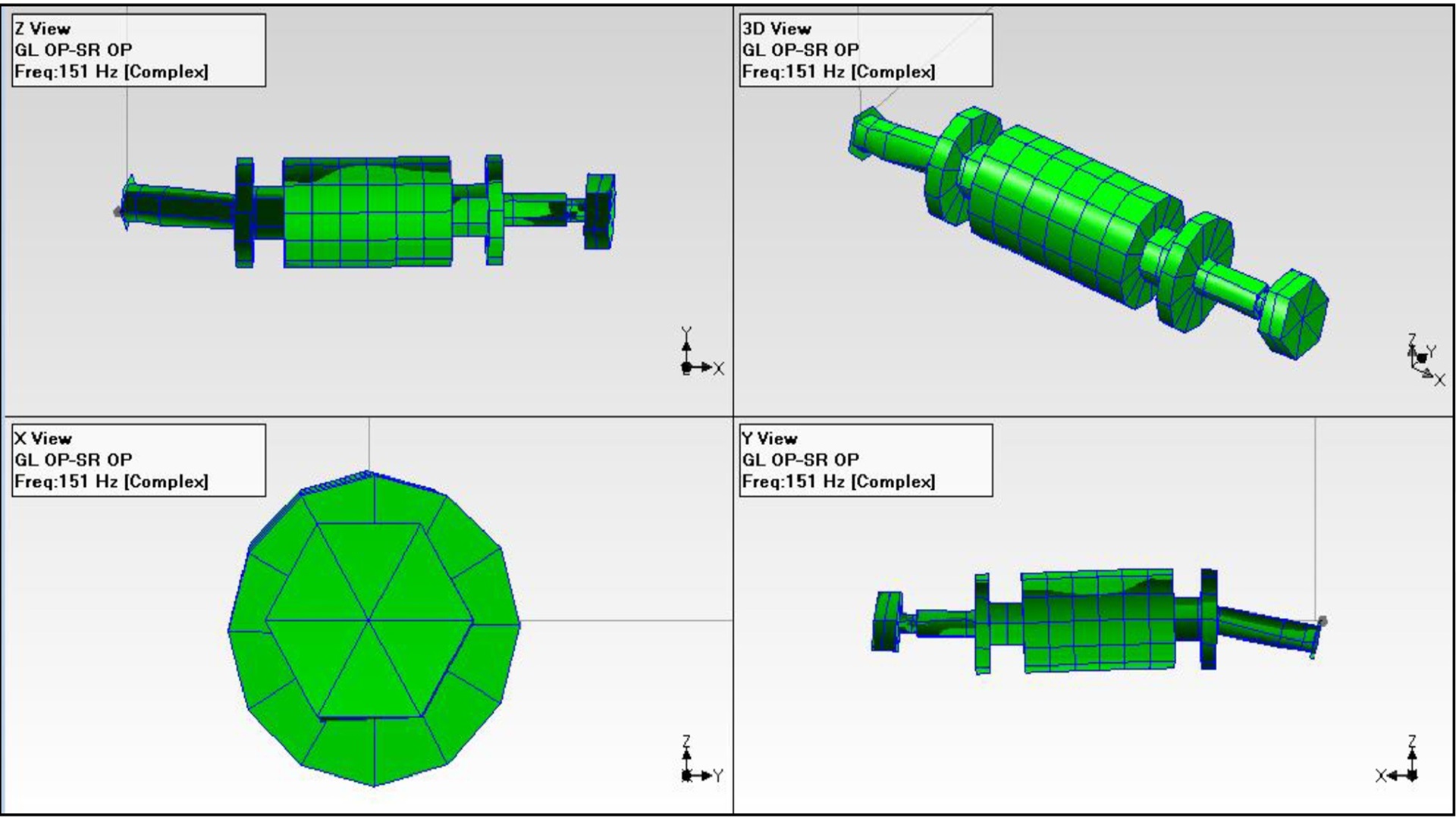

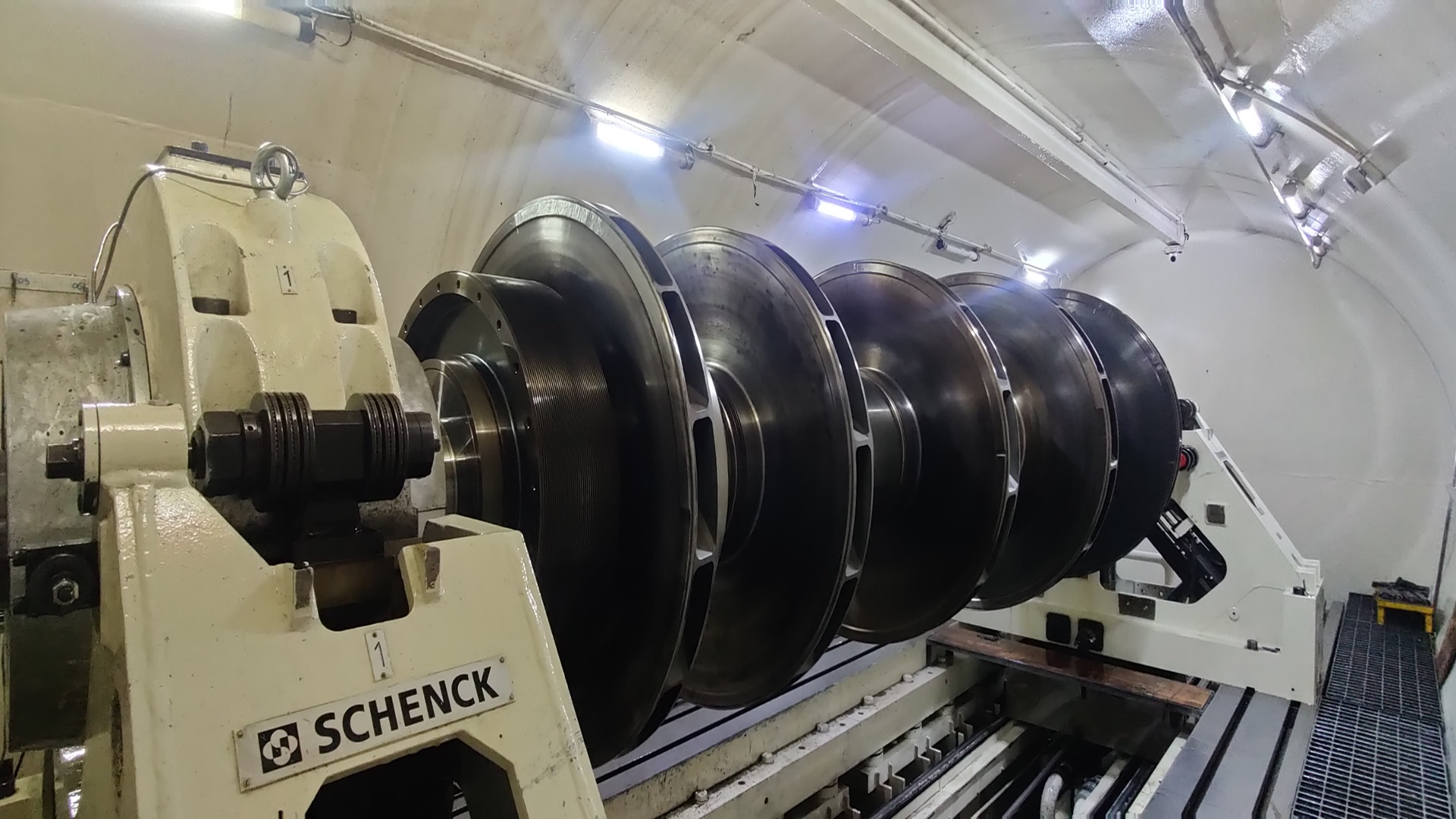

Industrial equipment often faces high noise and vibrations during installation, operation, and after refits. We excel at diagnosing and fixing these issues using advanced measurement and analysis techniques.

We troubleshoot a variety of machinery, including:

- Hydroelectric generators

- Gearboxes of steam turbine generators

- Gas compressors

- Fans and blowers

- Diesel generators (DG sets)

Let us help you reduce noise and vibration for smoother, quieter operations.

Read More